Record contract awarded to Rapp Hydema and Triplex

Rapp Hydema and Triplex have just been awarded a massive deck machinery contract for Australia’s Commonwealth Scientific and Research Organization (CSIRO). CSIRO selected Teekay Holdings Australia and Sembawang Shipyard Pte Ltd to carry out the design, build and commissioning of the vessel.

Denne artikkelen er tre år eller eldre.

Sembawang and Teekay appointed RALion (a joint-venture between Alion Science and Robert Allan LTD) to carry out the vessel basic design. The new vessel, named the Investigator, is scheduled for mid-2013 delivery. The consolidated deck -and handling machinery package is due for delivery in the 3rd quarter of 2012.

Rapp Hydema teamed up with Triplex in overcoming uncommonly fierce competition for this highly-coveted award. Project management at Rapp Hydema reported that the contract apparently comprises “the most comprehensive and largest-scale research system ever delivered.”

And given that this is the fifth major Rapp and Triplex research contract in the last 15 months— preceded by complete winch suites already contracted to outfit two U.S. government vessels (ARRV and NOAA FSV-6), along with contracts for complete outfitting of the new South African and Namibian research vessels under construction at STX Finland — there is certainly a basis for comparison. Furthermore, Rapp has been in the fishery & oceanographic research-and-survey winch business since 1977—providing over 50 deck machinery research packages to customers in over a dozen countries…

Following interactions between Teekay, Sembawang and the Designer throughout last year, Rapp Hydema staff travelled to Washington, DC in May this year for an introductory and clarification meeting. Subsequent interactions occurred in Europe, Singapore and Australia during the spring and summer. August marked the decision in favor of Rapp and Triplex.

Ultimately, Rapp staff executed comprehensive analysis of dynamic loads in order to identify related drag forces and available payloads. Given the mission of working at extreme water depths (wire and cable holding capacity from 6000-8800 meters), this proved no small task. All deck machinery systems will be designed for ambient operating temperatures of -30°C to + 45°C. Machinery is also subject to approval under the rules for Lifting Appliances in LRS for operations in up to Sea State 6. Throughout the deck machinery package, redundancy in powering and standardization of parts are characteristic.

The scientific research winch package includes six different winches with lifting capacities of 3.1 to 37.6 tons for a giant piston corer operation at extreme water depths. On the fisheries side, there are two Rapp TWS 7590E-T90 trawl winches, each with 35 tons of first-layer line pull. A net drum with dividers for the sweep lines is also included, along with two smaller utility winches.

Symbolic of the scale of the deck machinery package, the new vessel will include no less than three winch rooms—and yet even with such accommodations, space issues have posed a great challenge. Approximately 180 tons of deck and handling machinery, with an installed-power footprint of 1800 kW, has posed special challenges in design. In close cooperation with SSPL/Teekay and RALion, Rapp specialists are continuing work on best possible options for operational lay-out, wire-routing and weight-reduction approaches.

The CSIRO contract allows Rapp and Triplex to showcase latest technologies and R&D triumphs. Among others, the electric winch package features VFDs (variable-frequency drives) of the AFE (Active Front End) type. Drive voltage is 690-volt AC, 3-phase, 50 Hertz, which is fast becoming the standard for the research vessel mission. Given the challenges of Arctic-Antarctic operations, winches are to be placed below decks in order to reduce corrosion and ice-ups. Another newer technology aboard will be an Active Heave Compensation (AHC) package; Rapp has provided this technology to several customers in recent years, especially in the ROV and offshore oil sectors. The winches are also equipped with Rapp’s electrically-driven, electronic synchronized level wind systems, for easy adjustment and change in the spooling pitch. This level wind system has become the new standard for research winches in recent years.

Rapp is also providing its patented liquid-cooled motor, recipient of Offshore Technology Conference innovative technology award last year, to power some of the winches. Finally, Rapp is providing its latest mission-specific upgrades of its long-running PTS Pentagon winch control technology, in the Research C-Bus version (for the scientific winch package management) and Fisheries C-Bus (for the fishery winches suite). The Pentagon management system offers tension control and auto-rendering features, among various others.

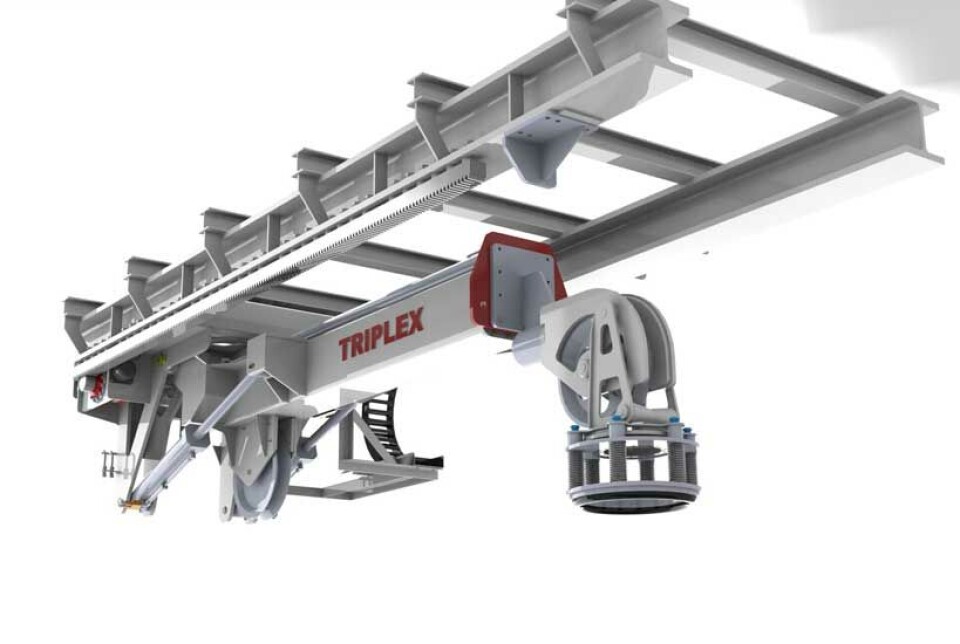

The Triplex side of the package is no less impressive in its scope with the special focus on efficient and safe handling of the different scientific packages.

A 30-ton telescopic corer boom, a Multi-Corer Pipe Handler, Corer Pipe Davits, a 20-ton Aft A-Frame with 170⁰ stroke and a 6-ton CTD Overhead Crane are just the highlights. There are two substantial power units, totaling 180kW, and two pair of Towing Booms (fore and aft) as well.