Wärtsilä Exhaust Gas Cleaning Systems selected for three more Color Line ships

Wärtsilä has been contracted to retrofit its Open Loop Scrubber systems on three additional vessels owned by Color Line, Norway’s largest cruise and ferry operator.

Denne artikkelen er tre år eller eldre.

This confirms Wärtsilä’s leading position in the scrubber market with 36 shipsets, totalling 75 scrubber units, either already installed or in the pipeline.

Each vessel will be fitted with four systems designed to rid the ships’ exhaust gases of harmful sulphur oxide (SOx) and particulate emissions. The Wärtsilä systems will enable the vessels to comply with current and anticipated environmental legislation, and to operate without restrictions in Emissions Control Areas (ECAs).

The contract was signed in September 2013 and it follows a similar order placed in June 2013 to retrofit Color Line’s SuperSpeed II ferry. The new contract covers the company’s SuperSpeed I, Color Magic and Color Fantasy ships. SuperSpeed I sails between Norway and Denmark, while the other two vessels link Oslo, Norway with Kiel, Germany.

“Color Line sees environmental issues as a priority and the use of Wärtsilä exhaust gas cleaning systems on another three of our vessels is a significant step towards our goals in this respect. The marine sector is obligated to operate in a more sustainable manner and we applaud Wärtsilä for its leadership in environmental performance enhancing technologies,” says Mr Jan Helge Pile, SVP Marine & Technical, Color Line Marine A/S.

“Wärtsilä continues to demonstrate its leadership in the delivery of innovative technologies that enable ship owners and operators to meet the dual challenges of environmental compliance and rising operating costs. Our exhaust cleaning systems are one of the increasingly important elements of this strategy, offering an efficient and cost-effective alternative to low- sulphur fuel,” says Mr Sigurd Jenssen, Director, Exhaust Gas Cleaning, Environmental Solutions, Wärtsilä Ship Power.

In addition to the equipment delivery, Wärtsilä has also assumed responsibility for the basic and detailed engineering and for the installation supervision.

“We see an increasing interest in our capability to supply turnkey installations,” says Mr Leonardo Sonzio, Director, Retrofit, Environmental Solutions, Wärtsilä Ship Power. “By working in close co-operation with the customer, Wärtsilä can develop tailored retrofit turnkey solutions that span the entire project, from the very first enquiry until the system is successfully delivered and installed. In addition to the Exhaust Gas Cleaning System retrofit projects, Wärtsilä also offers complete services for retrofitting Ballast Water Management Systems.”

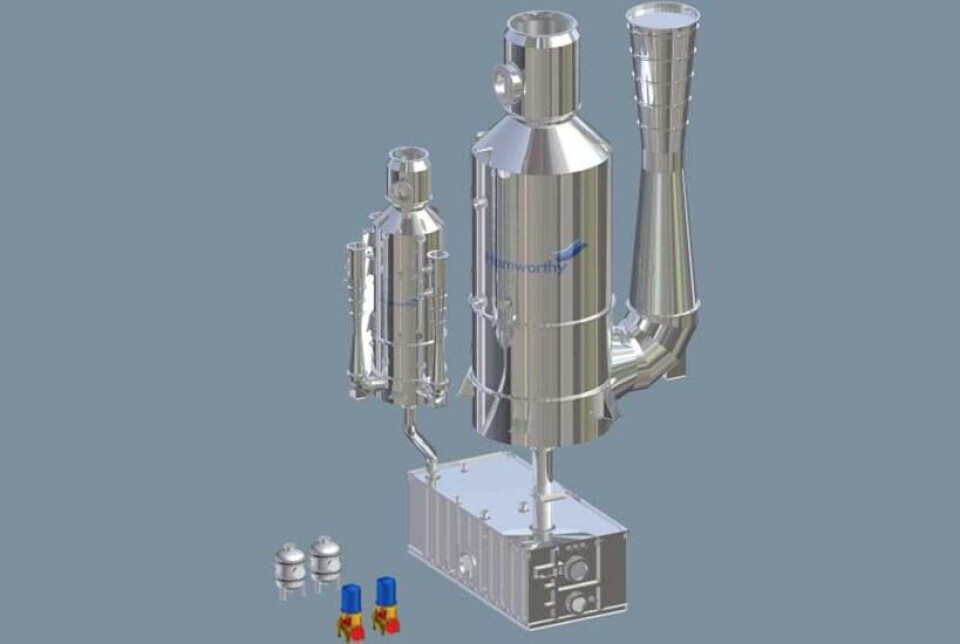

The Wärtsilä Open Loop Scrubber System

Wärtsilä Open Loop Scrubber

The system operates in an open loop using seawater to remove SOx from the exhaust. Exhaust gas enters the system and is sprayed with seawater in three different stages. The sulphur oxides in the exhaust react with the water to form sulphuric acid. Chemicals are not required since the natural alkalinity of seawater neutralizes the acid.

Wash water from the system is treated and monitored at the inlet and outlet to ensure that it conforms to all applicable discharge criteria. It can then be discharged into the sea with no risk of harm to the environment.